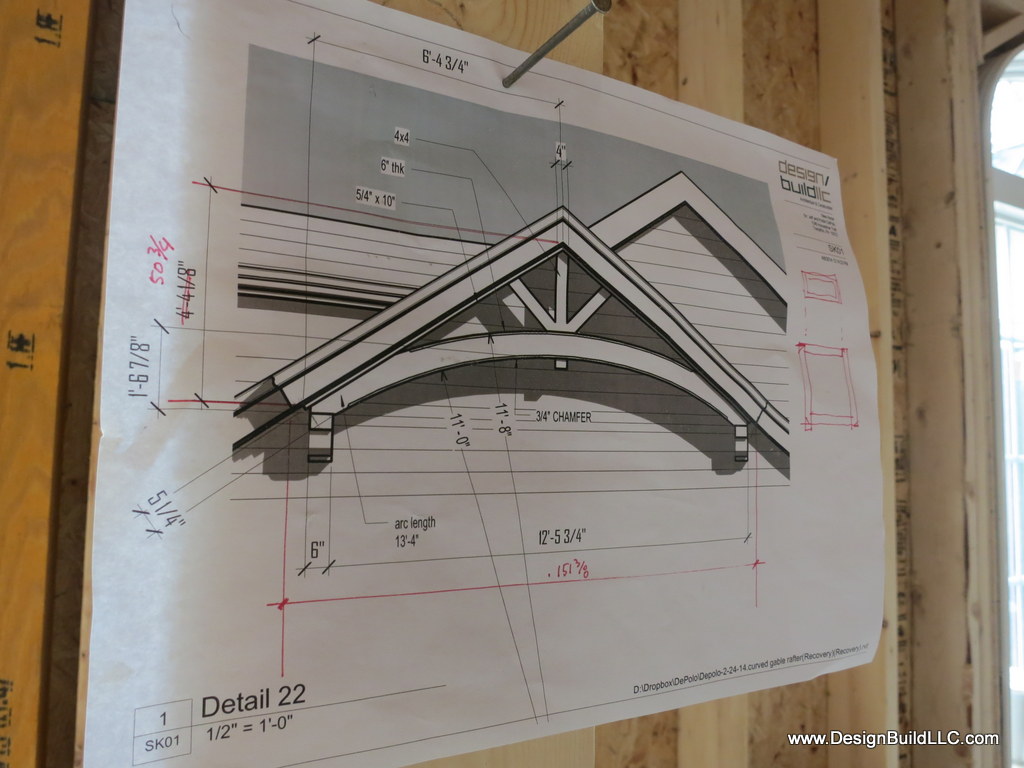

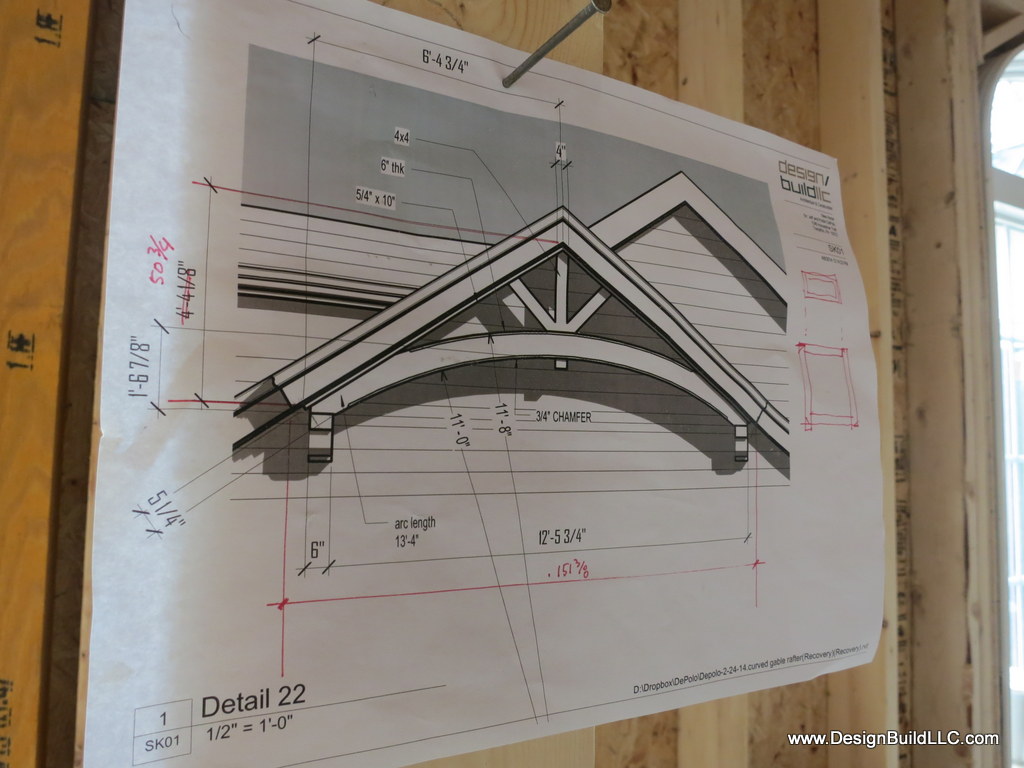

This exterior show truss is formed by heat bending the exterior trim material to 275 degrees then bending around a form to create the curved sides.

The arch, installed

Nailed it.

One of the things I love about being a design builder is the immediacy of translating concept into reality. Seeing ones lofty sketches with a 12d framing nail skewered through them is oddly satisfying. Here we've verified the dimensions of the area where the truss will fit.

Making the form

We transfer the form dimensions to a jig then clamp the heat formed 1x8's to it to form the curve.

The finished piece

is ready for finished details, sanding and preparation to install.

Ready for final finishing

adding beveled edges and offset reveals. It's a very large piece but proportioned right for its place in the facade.